Bending

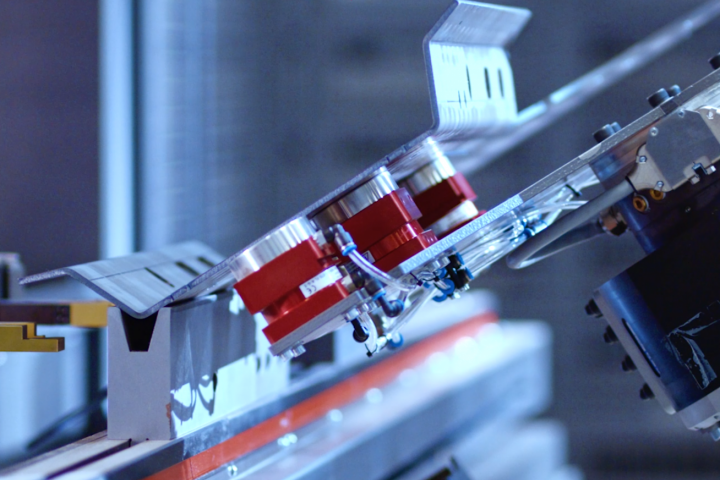

In our automatic laser bending cell, we have two fully robotic edging cells. The MES (Manufacturing Execution System) ensures that numerous machine communicate with each other. Thus, in this system, it communicates that laser-cut parts are ready for the next process step. These could be settlements, for example. The ‘press brake robot’ recognises this information and automatically sets the press brake for production. This means automatic tooling change and preparation of the correct bending program.

From our sheet warehouse, the laser-cut parts are then offered through the warehouse and the robot can start its production. When a pallet or production is ready, this same MES again sends a signal to our AMRs (Autonomous Mobile Robots). These are instructed to move the products to our ‘warehouse’. Before the products are presented to the warehouse, the production is checked for length, width and height using our Fly-by systems. With this data, a rack location is reserved and our semi-automatic narrow aisle trucks are activated to put the products away at the reserved location.

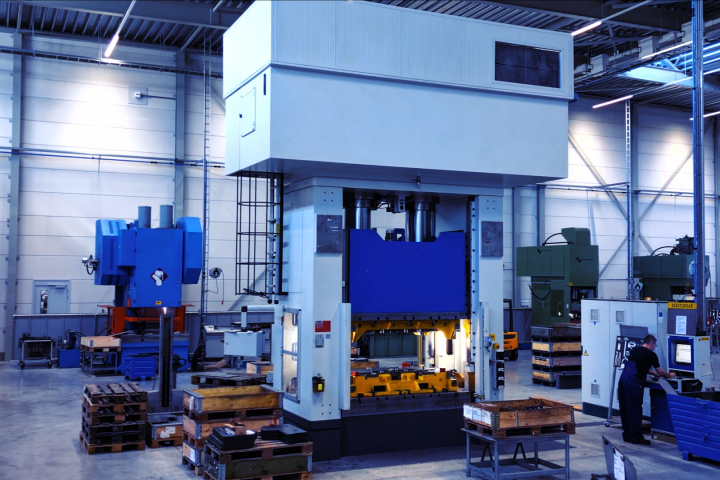

Apart from our fully automated robotic press brakes, we also have several CNC press brakes.